|

5.10 CAPACITY PLANNING

Design of the production system involves planning for the inputs, conversion process and outputs

of production operation. The effective management of capacity is the most important responsibility

of production management. The objective of capacity management (i.e., planning and control of

capacity) is to match the level of operations to the level of demand.

Capacity planning is to be carried out keeping in mind future growth and expansion plans,

market trends, sales forecasting, etc. It is a simple task to plan the capacity in case of stable

demand. But in practice the demand will be seldom stable. The fluctuation of demand creates

problems regarding the procurement of resources to meet the customer demand. Capacity decisions

|

are strategic in nature. Capacity is the rate of productive capability of a facility. Capacity is

usually expressed as volume of output per period of time.

Production managers are more concerned about the capacity for the following reasons:

_ Sufficient capacity is required to meet the customers demand in time.

_ Capacity affects the cost efficiency of operations.

_ Capacity affects the scheduling system.

_ Capacity creation requires an investment.

Capacity planning is the first step when an organization decides to produce more or new

products.

5.10.1 Measurement of Capacity Planning

The capacity of the manufacturing unit can be expressed in number of units of output per period.

In some situations measuring capacity is more complicated when they manufacture multiple

products. In such situations, the capacity is expressed as man-hours or machine hours. The

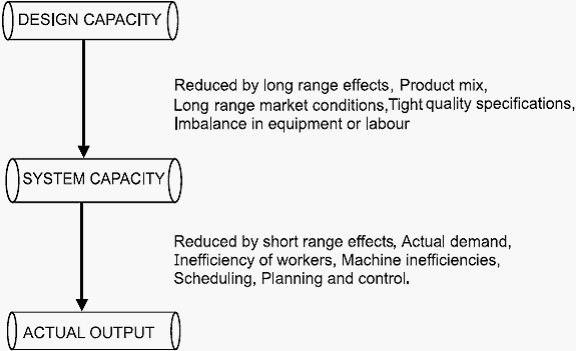

relationship between capacity and output is shown in Fig. 5.6.

1. Design capacity: Designed capacity of a facility is the planned or engineered rate of

output of goods or services under normal or full scale operating conditions.

For example, the designed capacity of the cement plant is 100 TPD (Tonnes per day).

Capacity of the sugar factory is 150 tonnes of sugarcane crushing per day.

2. System capacity: System capacity is the maximum output of the specific product or

product mix the system of workers and machines is capable of producing as an integrated whole.

System capacity is less than design capacity or at the most equal, because of the limitation of

product mix, quality specification, breakdowns. The actual is even less because of many factors

affecting the output such as actual demand, downtime due to machine/equipment failure,

unauthorised absenteeism.

Fig. 5.6 Capacity and output relationship

|

|

_________

___

_

_ _

_ __

____

___

The system capacity is less than design capacity because of long range uncontrollable

factors. The actual output is still reduced because of short-term effects such as, breakdown of

equipment, inefficiency of labour. The system efficiency is expressed as ratio of actual measured

output to the system capacity.

System Efficiency (SE) =

Actual output

System capacity

3. Licensed capacity: Capacity licensed by the various regulatory agencies or government

authorities. This is the limitation on the output exercised by the government.

4. Installed capacity: The capacity provided at the time of installation of the plant is called

installed capacity.

5. Rated capacity: Capacity based on the highest production rate established by actual trials

is referred to as rated capacity.

5.10.2 Process of Capacity Planning

Capacity planning is concerned with defining the long-term and the short-term capacity needs of

an organization and determining how those needs will be satisfied. Capacity planning decisions

are taken based upon the consumer demand and this is merged with the human, material and

financial resources of the organization.

Capacity requirements can be evaluated from two perspectives—long-term capacity strategies

and short-term capacity strategies.

1. LONG-TERM CAPACITY STRATEGIES

Long-term capacity requirements are more difficult to determine because the future demand and

technology are uncertain. Forecasting for five or ten years into the future is more risky and

difficult. Even sometimes company’s today’s products may not be existing in the future. Long

range capacity requirements are dependent on marketing plans, product development and

lifecycle

of the product. Long-term capacity planning is concerned with accommodating major

changes that affect overall level of the output in long-term. Marketing environmental assessment

and implementing the long-term capacity plans in a systematic manner are the major

responsibilities

of management. Following parameters will affect long range capacity decisions.

1. Multiple products: Company’s produce more than one product using the same facilities

in order to increase the profit. The manufacturing of multiple products will reduce the risk of

failure. Having more than one product helps the capacity planners to do a better job. Because

products are in different stages of their life-cycles, it is easy to schedule them to get maximum

capacity utilisation.

2. Phasing in capacity: In high technology industries, and in industries where technology

developments are very fast, the rate of obsolescence is high. The products should be brought into

the market quickly. The time to construct the facilities will be long and there is no much time as

the products should be introduced into the market quickly. Here the solution is phase in capacity

on modular basis. Some commitment is made for building funds and men towards facilities over

a

period of 3–5 years. This is an effective way of capitalising on technological breakthrough.

3. Phasing out capacity: The outdated manufacturing facilities cause excessive plant

|

|

closures and down time. The impact of closures is not limited to only fixed costs of plant and

machinery. Thus, the phasing out here is done with humanistic way without affecting the

community.

The phasing out options makes alternative arrangements for men like shifting them to other jobs

or to other locations, compensating the employees, etc.

2. SHORT-TERM CAPACITY STRATEGIES

Managers often use forecasts of product demand to estimate the short-term workload the facility

must handle. Managers looking ahead up to 12 months, anticipate output requirements for

different

products, and services. Managers then compare requirements with existing capacity and then

take decisions as to when the capacity adjustments are needed.

For short-term periods of up to one year, fundamental capacity is fixed. Major facilities will

not be changed. Many short-term adjustments for increasing or decreasing capacity are possible.

The adjustments to be required depend upon the conversion process like whether it is capital

intensive or labour intensive or whether product can be stored as inventory.

Capital intensive processes depend on physical facilities, plant and equipment. Short-term

capacity can be modified by operating these facilities more or less intensively than normal. In

labour intensive processes short-term capacity can be changed by laying off or hiring people or

by giving overtime to workers. The strategies for changing capacity also depend upon how long

the product can be stored as inventory.

The short-term capacity strategies are:

1. Inventories: Stock of finished goods during slack periods to meet the demand during

peak period.

2. Backlog: During peak periods, the willing customers are requested to wait and their

orders are fulfilled after a peak demand period.

3. Employment level (hiring or firing): Hire additional employees during peak demand

period and layoff employees as demand decreases.

4. Employee training: Develop multi-skilled employees through training so that they can

be rotated among different jobs. The multi-skilling helps as an alternative to hiring employees.

5. Subcontracting: During peak periods, hire the capacity of other firms temporarily to

make the component parts or products.

6. Process design: Change job contents by redesigning the job.

5.11 ROUTING

Routing may be defined as the selection of path which each part of the product will follow while

being transformed from raw materials to finished products. Path of the product will also give

sequence of operation to be adopted while being manufactured.

In other way, routing means determination of most advantageous path to be followed from

department to department and machine to machine till raw material gets its final shape, which

involves the following steps:

(a) Type of work to be done on product or its parts.

(b) Operation required to do the work.

(c) Sequence of operation required

.

|

|

_________

___

_

_ _

_ __

____

___

(d) Where the work will be done.

(e) A proper classification about the personnel required and the machine for doing the work.

For effective production control of a well-managed industry with standard conditions, the

routing plays an important role, i.e., to have the best results obtained from available plant

capacity. Thus routing provides the basis for scheduling, dispatching and follow-up.

5.11.1 Techniques of Routing

While converting raw material into required goods different operations are to be performed and

the selection of a particular path of operations for each piece is termed as ‘Routing’. This

selection of a particular path, i.e. sequence of operations must be the best and cheapest to have

the lowest cost of the final product. The various routing techniques are:

1. Route card: This card always accompanies with the job throughout all operations. This

indicates the material used during manufacturing and their progress from one operation to

another. In addition to this the details of scrap and good work produced are also recorded.

2. Work sheet: It contains

(a) Specifications to be followed while manufacturing.

(b) Instructions regarding routing of every part with identification number of machines and

work place of operation.

This sheet is made for manufacturing as well as for maintenance.

3. Route sheet: It deals with specific production order. Generally made from operation

sheets. One sheet is required for each part or component of the order. These includes the following:

(a) Number and other identification of order.

(b) Symbol and identification of part.

(c) Number of pieces to be made.

(d) Number of pieces in each lot—if put through in lots.

(e) Operation data which includes:

(i) List of operation on the part.

(ii) Department in which operations are to be performed.

(iii) Machine to be used for each operation.

(iv) Fixed sequence of operation, if any.

(f) Rate at which job must be completed, determined from the operation sheet.

4. Move order: Though this is document needed for production control, it is never used

for routing system. Move order is prepared for each operation as per operation sheet. On this

the quantity passed forward, scrapped and to be rectified are recorded. It is returned

to planning office when the operation is completed.

5.12 SCHEDULING

Scheduling can be defined as “prescribing of when and where each operation necessary to

manufacture the product is to be performed.”

It is also defined as “establishing of times at which to begin and complete each event or

|

|

__

_________

_

_ ________

__

_____

_

operation comprising a procedure”. The principle aim of scheduling is to plan the sequence of

work so that production can be systematically arranged towards the end of completion of all

products by due date.

5.12.1 Principles of Scheduling

1. The principle of optimum task size: Scheduling tends to achieve maximum efficiency

when the task sizes are small, and all tasks of same order of magnitude.

2. Principle of optimum production plan: The planning should be such that it imposes an

equal load on all plants.

3. Principle of optimum sequence: Scheduling tends to achieve the maximum efficiency

when the work is planned so that work hours are normally used in the same sequence.

5.12.2 Inputs to Scheduling

1. Performance standards: The information regarding the performance standards (standard

times for operations) helps to know the capacity in order to assign required machine

hours to the facility.

2. Units in which loading and scheduling is to be expressed.

3. Effective capacity of the work centre.

4. Demand pattern and extent of flexibility to be provided for rush orders.

5. Overlapping of operations.

6. Individual job schedules.

5.12.3 Scheduling Strategies

Scheduling strategies vary widely among firms and range from ‘no scheduling’ to very sophisticated

approaches.

These strategies are grouped into four classes:

1. Detailed scheduling: Detailed scheduling for specific jobs that are arrived from customers

is impracticable in actual manufacturing situation. Changes in orders, equipment breakdown, and

unforeseen events deviate the plans.

2. Cumulative scheduling: Cumulative scheduling of total work load is useful especially

for long range planning of capacity needs. This may load the current period excessively and under

load future periods. It has some means to control the jobs.

3. Cumulative detailed: Cumulative detailed combination is both feasible and practical

approach. If master schedule has fixed and flexible portions.

4. Priority decision rules: Priority decision rules are scheduling guides that are used

independently and in conjunction with one of the above strategies, i.e., first come first serve.

These are useful in reducing Work-In-Process (WIP) inventory.

|

_________

___

_

_ _

_ __

____

__

5.12.4 Types of Scheduling

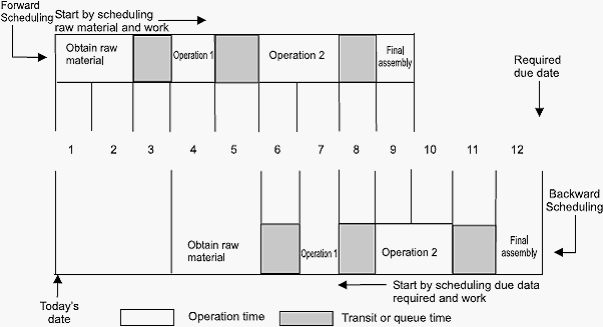

Types of scheduling can be categorized as forward scheduling and backward scheduling.

1. Forward scheduling is commonly used in job shops where customers place their orders

on “needed as soon as possible” basis. Forward scheduling determines start and finish times of

next priority job by assigning it the earliest available time slot and from that time, determines

when the job will be finished in that work centre. Since the job and its components start as early

as possible, they will typically be completed before they are due at the subsequent work centres

in the routing. The forward method generates in the process inventory that are needed at

subsequent work centres and higher inventory cost. Forward scheduling is simple to use and it

gets jobs done in shorter lead times, compared to backward scheduling.

2. Backward scheduling is often used in assembly type industries and commit in advance

to specific delivery dates. Backward scheduling determines the start and finish times for waiting

jobs by assigning them to the latest available time slot that will enable each job to be completed

just when it is due, but done before. By assigning jobs as late as possible, backward scheduling

minimizes inventories since a job is not completed until it must go directly to the next work centre

on its routing. Forward and backward scheduling methods are shown in Fig. 5.7.

Fig. 5.7 Forward and backward scheduling

5.13 SCHEDULING METHODOLOGY

The scheduling methodology depends upon the type of industry, organization, product, and level

of sophistication required. They are:

1.

Charts and boards,

|

|

___ _________

_

_ ________

__

_____

_

2. Priority decision rules, and

3. Mathematical programming methods.

1. Gantt Charts and Boards

Gantt charts and associated scheduling boards have been extensively used scheduling devices in

the past, although many of the charts are now drawn by computer. Gantt charts are extremely

easy to understand and can quickly reveal the current or planned situation to all concerned. They

are used in several forms, namely,

(a) Scheduling or progress charts, which depicts the sequential schedule;

(b) Load charts, which show the work assigned to a group of workers or machines; and

(c) Record a chart, which are used to record the actual operating times and delays of

workers and machines.

2. Priority Decision Rules

Priority decision rules are simplified guidelines for determining the sequence in which jobs will

be done. In some firms these rules take the place of priority planning systems such as MRP

systems. Following are some of the priority rules followed.

Symbol Priority rule

FCFS First come, first served

EDO Earliest due date

LS Least slack (that is, time due less processing time)

SPT Shortest processing time

LPT Longest processing time

PCO Preferred customer order

RS Random selection

3. Mathematical Programming Methods

Scheduling is a complex resource allocation problem. Firms process capacity, labour skills, materials

and they seek to allocate their use so as to maximize a profit or service objective, or perhaps

meet a demand while minimizing costs.

The following are some of the models used in scheduling and production control.

(a) Linear programming model: Here all the constraints and objective functions are

formulated as a linear equation and then problem is solved for optimality. Simplex method,

transportation methods and assignment method are major methods used here.

(b) PERT/CPM network model: PERT/CPM network is the network showing the sequence

of operations for a project and the precedence relation between the activities to be completed.

Note: Scheduling is done in all the activities of an organisation i.e., production, maintenance etc. Therefore,

all the methods and techniques of scheduling is used for maintenance management (Ref. Chapter 8).

|

|

_________

___

_

_ _

_ __

____

___

EXERCISES

Section A

1. What do you mean by production planning and control?

2. What do you mean by aggregate planning?

3. What is master production schedule?

4. What is material requirement planning?

5. What is capacity planning?

6. What is routing?

7. What is scheduling?

8. Mention the types of scheduling.

Section B

1. Why do you need production planning and control?

2. What are the objective of production planning and control?

3.

What are the guidelines for aggregate planning?

4. Explain the functions of master production schedule.

5.

Explain the objective of MRP.

6. How do you measure capacity?

7. Explain the techniques of routing.

8. What are the inputs to scheduling?

9. Explain the scheduling strategies.

Section C

1. Discuss the phases of production planning and control.

2. Discuss the functions of PP & C.

3. Discuss the operations planning and scheduling systems.

4. Discuss the aggregate plan and master schedule.

5. Discuss the MRP system.

6. Discuss the process of capacity planning.

7. Discuss the scheduling methods.

Skill Development

FAST FOOD RESTAURANT VISIT: Get the information for the following questions:

1. Phase of production planning and production control.

2. Planning for the demand fluctuation.

3. Items are prepared to order or with forecast.

4. Procedures to manufacture pizza.

5. Scheduling the orders (i.e. first come first schedule or largest proceeding time and shortest

proceeding time etc.)

|

___ _________

_

_ ________

__

_____

_

CASELET

ESCOM-COPING WITH RUNWAY

CAPACITY NEEDS

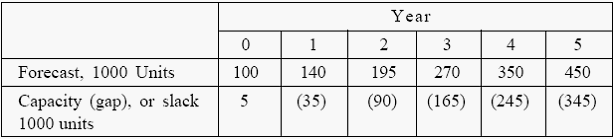

ESCOM is a producer of electronic home appliances, including VHS (Video Home System)

television recorders, located in northern California. The packaged product weighs about 75 kg.

ESCOM was not the innovator of the system. Rather, its managers sat back and let RCA and

others develop the market, and ESCOM is currently producing under license agreements. ESCOM

has a conscious strategy of being a follower with new product innovations. It does not have the

financial resources to be a leader in research and development.

ESCOM’s present opportunity is indicated by the fact that industry sales of VHS recorders

have increased 30 per cent per year for the past two years, and forecasts for the next year and

the two following are even more enticing. ESCOM has established a 10 per cent market share

position and feels that it can at least maintain this position if it has the needed capacity; it could

possibly improve its market share if competitors fail to provide capacity at the time it is needed.

Year

The forecasts and capacity gaps are indicated in Table. ESCOM regards the first year

forecast as being quite solid, based on its present market share and a compilation of several

industry forecasts from different sources. It is less sure about the forecasts for future years, but

it is basing these forecasts on patterns for both black and white and color TV sales during their

product life cycles.

ESCOM’s VHS model has a factory price of Rs 600. Variable costs are 70 percent of the

price. Inventory carrying costs are 20 per cent of inventory value, 15 percentage points of which

represents the cost of capital. ESCOM’s facility planners estimate that a 40,000 unit plant can

be built for Rs. 5 million and a 200,00 unit plant, for Rs. 10 million. Land and labour are available

in the area, and either size plant can be built within a year.

(a) What capacity plans do you think ESCOM should make for next year? Why?

(b) What longer-term capacity plans should ESCOM make? Why?

(c) What are the implications of these plans for marketing, distribution, and production?

[Source: Modern Production/Operations Management by Elwood S.Buffa & Rakesh K.Sarin]

|

|

CHAPTER OUTLINE

131

QUALITY CONTROL

6.1 Introduction

6.2 Quality

6.3 Control

6.4 Inspection

6.5 Quality Control

6.6 Statistical Process Control

6

6.7 Quality Circles

6.8 Total Quality Management (TQM)

6.9 ISO 9000 Series

6.10 Appliation ISO 9000: ISO 14000 Series

• Exercises

• Skill Development

• Caselet

6.1 INTRODUCTION

In any business organization, profit is the ultimate goal. To achieve this, there are several

approaches. Profit may be maximized by cutting costs for the same selling price per unit. If it

is a monopolistic business, without giving much of importance to the cost reduction programs, the

price may be fixed suitably to earn sufficient profit. But, to survive in a competitive business

environment, goods and services produced by a firm should have the minimum required quality.

Extra quality means extra cost. So, the level of quality should be decided in relation to other

factors such that the product is well absorbed in the market. In all these cases, to have repeated

sales and thereby increased sales revenue, basic quality is considered to be one of the supportive

factors. Quality is a measure of how closely a good or service conforms to specified standard.

Quality standards may be any one or a combination of attributes and variables of the product

being manufactured. The attributes will include performance, reliability, appearance, commitment

to delivery time, etc., variables may be some measurement variables like, length, width, height,

diameter, surface finish, etc.

|

|

Most of the above characteristics are related to products. Similarly, some of the quality

characteristics of services are meeting promised due dates, safety, comfort, security, less waiting

time and so forth. So, the various dimensions of quality are performance, features, reliability,

conformance, durability, serviceability, aesthetics, perceived quality, safety, comfort, security,

commitment to due dates, less waiting time, etc.

6.2 QUALITY

Different meaning could be attached to the word quality under different circumstances. The word

quality does not mean the quality of manufactured product only. It may refer to the quality of

the process (i.e., men, material, and machines) and even that of management. Where the quality

manufactured product referred as or defined as “Quality of product as the degree in which it

fulfills the requirement of the customer. It is not absolute but it judged or realized by comparing

it with some standards”.

Quality begins with the design of a product in accordance with the customer specification

further it involved the established measurement standards, the use of proper material, selection

of suitable manufacturing process etc., quality is a relative term and it is generally used with

reference to the end use of the product.

Crosby defined as “Quality is conformance to requirement or specifications”.

Juran defined as “Quality is fitness for use”. “The Quality of a product or service is the

fitness of that product or service for meeting or exceeding its intended use as required by the

customer.”

6.2.1 Fundamental Factors Affecting Quality

The nine fundamental factors (9 M’s), which are affecting the quality of products and services,

are: markets, money, management, men, motivation, materials, machines and mechanization.

Modern information methods and mounting product requirements.

1. Market: Because of technology advancement, we could see many new products to

satisfy customer wants. At the same time, the customer wants are also changing dynamically.

So, it is the role of companies to identify needs and then meet it with existing technologies or

by developing new technologies.

2. Money: The increased global competition necessitates huge outlays for new equipments

and process. This should be rewarded by improved productivity. This is possible by minimizing

quality costs associated with the maintenance and improvements of quality level.

3. Management: Because of the increased complex structure of business organization, the

quality related responsibilities lie with persons at different levels in the organization.

4. Men: The rapid growth in technical knowledge leads to development of human resource

with different specialization. This necessitates some groups like, system engineering group to

integrate the idea of full specialization.

|

|

_______ __

____

___

5. Motivation: If we fix the responsibility of achieving quality with each individual in the

organization with proper motivation techniques, there will not be any problem in producing the

designed quality products.

6. Materials: Selection of proper materials to meet the desired tolerance limit is also an

important consideration. Quality attributes like, surface finish, strength, diameter etc., can be

obtained by proper selection of material.

7. Machines and mechanization: In order to have quality products which will lead to

higher productivity of any organization, we need to use advanced machines and mechanize

various operations.

8. Modern information methods: The modern information methods help in storing and

retrieving needed data for manufacturing, marketing and servicing.

9. Mounting product requirements: Product diversification to meet customers taste leads

to intricacy in design, manufacturing and quality standards. Hence, companies should plan adequate

system to tackle all these requirements.

6.3 CONTROL

The process through which the standards are established and met with standards is called control.

This process consists of observing our activity performance, comparing the performance with

some standard and then taking action if the observed performance is significantly too different

from the standards.

The control process involves a universal sequence of steps as follows:

1. Choose the control object

2. Choose a unit of measure

3. Set the standard value

4. Choose a sensing device which can measure

5. Measure actual performance

6. Interpret the difference between actual and standard

7. Taking action.

6.3.1 Need for Controlling Quality

In the absence of quality, the following will result:

1. No yardstick for comparing the quality of goods/services.

2. Difficulty in maintaining consistency in quality.

3. Dissatisfied customers due to increased maintenance and operating costs of products/services.

4. Increased rework cost while manufacturing products/providing services.

5. Reduced life time of the products/services.

6. Reduced flexibility with respect to usage of standard spare parts.

7. Hence, controlling quality is an essential activity.

|

|

6.4 INSPECTION

Inspection is an important tool to achieve quality concept. It is necessary to assure confidence

to manufacturer and aims satisfaction to customer. Inspection is an indispensable tool of modern

manufacturing process. It helps to control quality, reduces manufacturing costs, eliminate scrap

losses and assignable causes of defective work.

The inspection and test unit is responsible for appraising the quality of incoming raw materials

and components as well as the quality of the manufactured product or service. It checks the

components at various stages with reference to certain predetermined factors and detecting and

sorting out the faulty or defective items. It also specified the types of inspection devices to use

and the procedures to follow to measure the quality characteristics.

Inspection only measures the degree of conformance to a standard in the case of variables.

In the case of attributes inspection merely separates the nonconforming from the conforming.

Inspection does not show why the nonconforming units are being produced.

Inspection is the most common method of attaining standardization, uniformity and quality of

workmanship. It is the cost art of controlling the production quality after comparison with the

established standards and specifications. It is the function of quality control. If the said item does

not fall within the zone of acceptability it will be rejected and corrective measure will be applied

to see that the items in future conform to specified standards.

6.4.1 Objectives of Inspection

1. To detect and remove the faulty raw materials before it undergoes production.

2. To detect the faulty products in production whenever it is detected.

3. To bring facts to the notice of managers before they become serous to enable them

discover weaknesses and over the problem.

4. To prevent the substandard reaching the customer and reducing complaints.

5. To promote reputation for quality and reliability of product.

6.4.2 Purpose of Inspection

1. To distinguish good lots from bad lots.

2. To distinguish good pieces from bad pieces.

3. To determine if the process is changing.

4. To determine if the process is approaching the specification limits.

5. To rate quality of product.

6. To rate accuracy of inspectors.

7. To measure the precision of the measuring instrument.

8. To secure products-design information.

9. To measure process capability.

|

|

6.4.3 Types of Inspection

Types of inspection are:

1. Floor inspection 2. Centralized inspection

3. Combined inspection 4. Functional inspection

5. First piece inspection 6. Pilot piece inspection

7. Final inspection

1. F

LOOR

I

NSPECTION

In this system, the inspection is performed at the place of production. It suggests the checking of

materials in process at the machine or in the production time by patrolling inspectors. These

inspectors move from machine to machine and from one to the other work centres. Inspectors have

to be highly skilled. This method of inspection minimize the material handling, does not disrupt the

line layout of machinery and quickly locate the defect and readily offers field and correction.

Advantages

1. Detection of errors of the source reduces scrap and rework.

2. Correction is done before it affects further production, resulting in saving cost of

unnecessary work on defective parts.

3. Material handling time is reduced.

4. Job satisfaction to worker as he can’t be held responsible for bad work at a later date.

5. Greater number of pieces can be checked than a sample size.

6. Does not delay in production.

Disadvantages

1. Delicate instruments can be employed.

2. Measuring or inspection equipment have to be recalibrated often as they are subjected

to wear or dust.

3. High cost of inspection because of numerous sets of inspections and skilled inspectors.

4. Supervision of inspectors is difficult due to vibration.

5. Pressure on inspector.

6. Possibility of biased inspection because of worker.

Suitability

1. Heavy products are produced.

2. Different work centres are integrated in continuous line layout.

2. CENTRALISED INSPECTION

Inspection is carried in a central place with all testing equipment, sensitive equipment is housed

in air-conditioned area. Samples are brought to the inspection floor for checking. Centralised

inspection may locate in one or more places in the manufacturing industry.

|

|

___ _________

_

_ ________

__

_____

_

Advantages

1. Greater degree of inspection due to sensitive equipment.

2. Less number of inspectors and tools.

3. Equipment needs less frequency of recalibration.

4. Cost of inspection is reduced.

5. Unbiased inspection.

6. Supervision of inspectors made possible.

7. No distraction to the inspector.

Disadvantages

1. Defects of job are not revealed quickly for prevention.

2. Greater material handling.

3. High cost as products are subjected to production before they are prevented.

4. Greater delay in production.

5. Inspection of heavy work not possible.

6. Production control work is more complicated.

7. Greater scrap.

3. COMBINED INSPECTION

Combination of two methods whatever may be the method of inspection, whether floor or central.

The main objective is to locate and prevent defect which may not repeat itself in subsequent

operation to see whether any corrective measure is required and finally to maintain quality

economically.

4. F

UNCTIONAL

I

NSPECTION

This system only checks for the main function, the product is expected to perform. Thus an

electrical motor can be checked for the specified speed and load characteristics. It does not

reveal the variation of individual parts but can assure combined satisfactory performance of all

parts put together. Both manufacturers and purchasers can do this, if large number of articles

are needed at regular intervals. This is also called assembly inspection.

5. FIRST PIECE OR FIRST-

OFF

I

NSPECTIONS

First piece of the shift or lot is inspected. This is particularly used where automatic machines are

employed. Any discrepancy from the operator as machine tool can be checked to see that the

product is within in control limits. Excepting for need for precautions for tool we are check and

disturbance in machine set up, this yields good result if the operator is careful.

6. P

ILOT

P

IECE

I

NSPECTION

This is done immediately after new design or product is developed. Manufacturer of product is done

either on regular shop floor if production is not disturbed. If production is affected to a large extent,

the product is manufactured in a pilot plant. This is suitable for mass production and products involving

large number of components such as automobiles aeroplanes etc., and modification are design or

manufacturing process is done until satisfactory performance is assured or established.

|

|

_______ __

____

___

7. F

INAL

I

NSPECTION

This is also similar to functional or assembly inspection. This inspection is done only after completion

of work. This is widely employed in process industries where there is not possible such as,

electroplating or anodizing products. This is done in conjunction with incoming material inspection.

6.4.4 Methods of Inspection

There are two methods of inspection. They are: 100% inspection and sampling inspection.

1. 100% I

NSPECTION

This type will involve careful inspection in detail of quality at each strategic point or stage of

manufacture where the test is involved is non-destructive and every piece is separately inspected.

It requires more number of inspectors and hence it is a costly method. There is no sampling error.

This is subjected to inspection error arising out of fatigue, negligence, difficulty of supervision etc.

Hence, completer accuracy of influence is seldom attained. It is suitable only when a small

number of pieces are there or a very high degree of quality is required. Example: Jet engines,

aircraft, medical and scientific equipment.

2. S

AMPLING

I

NSPECTION

In this method randomly selected samples are inspected. Samples taken from different patches

of products are representatives. If the sample proves defective, the entire concerned is to be

rejected or recovered. Sampling inspection is cheaper and quicker. It requires less number of

Inspectors. It is subjected to sampling errors but the magnitude of sampling error can be estimated.

In the case of destructive test, random or sampling inspection is desirable. This type of inspection

governs wide currency due to the introduction of automatic machines or equipments which are

less susceptible to chance variable and hence require less inspection, suitable for inspection of

products which have less precision importance and are less costly. Example: Electrical bulbs,

radio bulbs, washing machine etc.

6.4.5 Drawbacks of Inspection

Following are the disadvantages of inspection:

1. Inspection adds to the cost of the product but not for its value.

2. It is partially subjective, often the inspector has to judge whether a products passes or

not.

3. Fatigue and Monotony may affect any inspection judgment.

4. Inspection merely separates good and bad items. It is no way to prevent the production

of bad items.

6.5 QUALITY CONTROL

Quality Control (QC) may be defined as a system that is used to maintain a desired level of

quality in a product or service. It is a systematic control of various factors that affect the quality

of the product. It depends on materials, tools, machines, type of labour, working conditions etc.

|

|

___ _________

_

_ ________

__

_____

_

QC is a broad term, it involves inspection at particular stage but mere inspection does not mean

QC. As opposed to inspection, in quality control activity emphasis is placed on the quality future

production. Quality control aims at prevention of defects at the source, relies on effective

feedback system and corrective action procedure. Quality control uses inspection as a valuable tool.

According to Juran “Quality control is the regulatory process through which we measure

actual quality performance, compare it with standards, and act on the difference”. Another

definition of quality control is from ANSI/ASQC standard (1978) quality control is defined as

“The operational techniques and the activities which sustain a quality of product or service that

will satisfy given needs; also the use of such techniques and activities”.

Alford and Beatty define QC as “In the broad sense, quality control is the mechanism by

which products are made to measure up to specifications determined from customers, demands

and transformed into sales engineering and manufacturing requirements, it is concerned with

making things right rather than discovering and rejecting those made wrong”.

6.5.1 Types of Quality Control

QC is not a function of any single department or a person. It is the primary responsibility of any

supervisor to turn out work of acceptable quality. Quality control can be divided into three main

sub-areas, those are:

1. Off-line quality control, 2. Statistical process control, and 3. Acceptance sampling plans.

1. Off-line quality control: Its procedure deal with measures to select and choose

controllable product and process parameters in such a way that the deviation between the

product or process output and the standard will be minimized. Much of this task is accomplished

through product and process design.

Example: Taguchi method, principles of experimental design etc.

2. Statistical process control: SPC involves comparing the output of a process or a

service with a standard and taking remedial actions in case of a discrepancy between the two.

It also involves determining whether a process can produce a product that meets desired

specification or requirements. On-line SPC means that information is gathered about the product,

process, or service while it is functional. The corrective action is taken in that operational phase.

This is real-time basis.

3. Acceptance sampling plans: A plan that determines the number of items to sample and

the acceptance criteria of the lot, based on meeting certain stipulated conditions (such as the risk

of rejecting a good lot or accepting a bad lot) is known as an acceptance sampling plan.

6.5.2 Steps in Quality Control

Following are the steps in quality control process:

1. Formulate quality policy.

2. Set the standards or specifications on the basis of customer’s preference, cost and profit.

3. Select inspection plan and set up procedure for checking.

4. Detect deviations from set standards of specifications.

5. Take corrective actions or necessary changes to achieve standards.

|

|

_______ __

____

__

6. Decide on salvage method i.e., to decide how the defective parts are disposed of, entire

scrap or rework.

7. Coordination of quality problems.

8. Developing quality consciousness both within and outside the organization.

9. Developing procedures for good vendor-vendee relations.

6.5.3 Objectives of Quality Control

Following are the objectives of quality control:

1. To improve the companies income by making the production more acceptable to the

customers, i.e., by providing long life, greater usefulness, maintainability etc.

2. To reduce companies cost through reduction of losses due to defects.

3. To achieve interchangeability of manufacture in large scale production.

4. To produce optimal quality at reduced price.

5. To ensure satisfaction of customers with productions or services or high quality level, to

build customer goodwill, confidence and reputation of manufacturer.

6. To make inspection prompt to ensure quality control.

7. To check the variation during manufacturing.

The broad areas of application of quality control are incoming material control, process

control and product control.

6.5.4 Benefits of Quality Control

_

Improving the quality of products and services.

_

Increasing the productivity of manufacturing processes, commercial business, corporations.

_

Reducing manufacturing and corporate costs.

_

Determining and improving the marketability of products and services.

_

Reducing consumer prices of products and services.

_

Improving and/or assuring on time deliveries and availability.

_

Assisting in the management of an enterprise.

6.5.5 Seven Tools for Quality Control

To make rational decisions using data obtained on the product, or process, or from the consumer,

organizations use certain graphical tools. These methods help us learn about the characteristics

of a process, its operating state of affairs and the kind of output we may expect from it. Graphical

methods are easy to understand and provide comprehensive information; they are a viable tool

for the analysis of product and process data. These tools are effect on quality improvement. The

seven quality control tools are:

1. Pareto charts 2. Check sheets 3. Cause and effect diagram

4. Scatter diagrams 5. Histogram 6. Graphs or flow charts

7. Control charts

|

__ _________

_

_ ________

__

_____

_

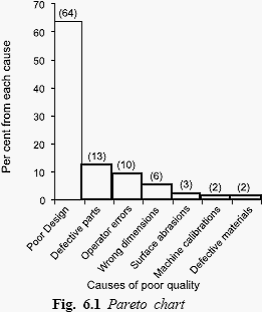

1. P

ARETO CHARTS

Pareto charts help prioritize by arranging them in decreasing order of importantce. In an environment

of limited resources these diagrams help companies to decide on the order in which they should

address problems. The Pareto analysis can be used to identify the problem in a number of forms.

(a) Analysis of losses by material (number or past number).

(b) Analysis of losses by process i.e., classification of defects or lot rejections in terms of

the process.

(c) Analysis of losses by product family.

(d) Analysis by supplier across the entire spectrum of purchases.

(e) Analysis by cost of the parts.

(f) Analysis by failure mode.

Example: The Fig. 6.1 shows a Pareto chart of reasons for poor quality. Poor design will

be the major reason, as indicated by 64%. Thus, this is the problem that the manufacturing unit

should address first.

A — Poor Design B — Defective Parts

C — Operator Error D — Wrong Dimensions

E — Surface Abrasion F — Machine Calibrations

G — Defective Material

2. CHECK SHEETS

Check sheets facilitate systematic record keeping or data collection observations are recorded as

they happen which reveals patterns or trends. Data collection through the use of a checklist is

often the first step in analysis of quality problem. A checklist is a form used to record the

frequency of occurrence of certain product or service characteristics related to quality. The

characteristics may be measurable on a continuous scale such as weight, diameter, time or length.

|

_______ __

____

___

Example: The table is a check sheet for an organization’s computer related problems.

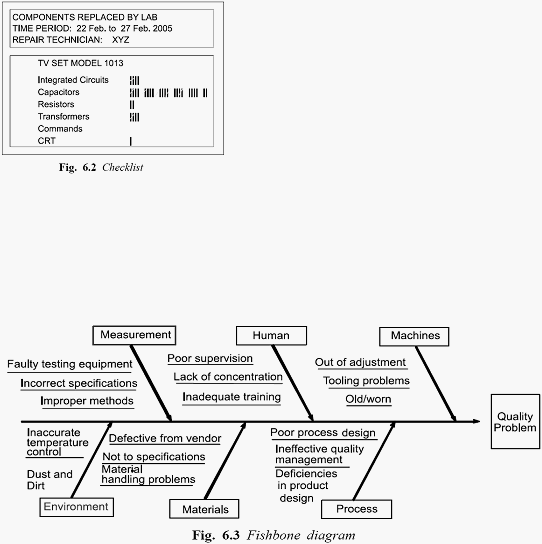

Fig. 6.2 Checklist

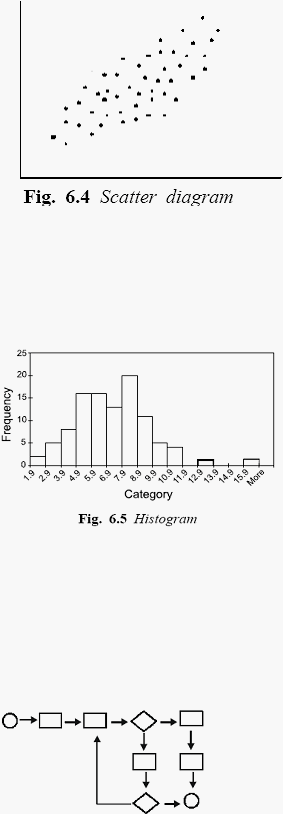

3. CAUSE AND EFFECT DIAGRAM

It is sometimes called as Fish-bone diagram. It is first developed by Kaorv Ishikawa in 1943 and

is sometimes called as Ishikawa diagram. The diameter helps the management trace customer

complaints directly to the operations involved. The main quality problem is referred to Fish-head;

the major categories of potential cause structural bones and the likely specific causes to ribs. It

explores possible causes of problems, with the intention being to discover the root causes. This

diagram helps identify possible reasons for a process to go out of control as well as possible

effects on the process.

Fig. 6.3 Fishbone diagram

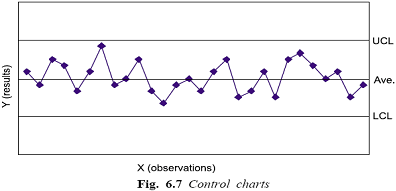

4. SCATTER DIAGRAM (SCATTER PLOTS)

It often indicates the relationship between two variables. They are often used as follow-ups to

a cause and effect analysis to determine whether a stated cause truly does impact the quality

characteristics.

|

Example: The above figure plots advertising expenditure against company sales and indicates

a strong positive relationship between the two variables. As the level of advertising expenditure

increases sales tend to increase.

5. H

ISTOGRAM

(

OR

) B

AR CHARTS

It displays the large amounts of data that are difficult to interpret in their raw form. A histogram

summarizes data measured on a continuous scale showing the frequency distribution of some

quality characteristics (in statistical terms the central tendency and the dispersion of the data).

Often the mean of the data is indicated on the histogram. A bar chart is a series of bare

representing the frequency of occurrence of data characteristics, the bar height indicates the

number of times a particular quality characteristic was observed.

6. FLOW CHARTS (

OR

) GRAPHS

It shows the sequence of events in a process. They are used for manufacturing and service operations.

Flow charts are often used to diagram operational procedures to simplify the system. They can identify

bottlenecks, redundant steps and non-value added activities. A realistic flow chart can be constructed

by using the knowledge of the person who are directly involved in the particular process. The flow

chart can be identifies where delays can occur.

_______ __

____

___

|

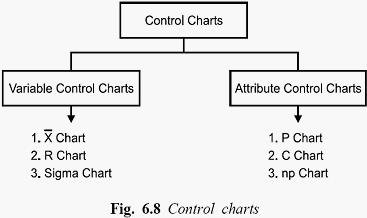

7. CONTROL CHARTS

It distinguish special causes of variations from common causes of variation. They are used to

monitor and control process on an ongoing basis. A typical control chart plots a selected quality

characteristic found from sub-group of observations as a function of sample number. Characteristics

such as sample average, sample range and sample proportion of non-conforming units are plotted.

The centre line on a control chart represents the average value of characteristics being plotted.

Two limits know as the upper control limit (UCL) and lower control limit (LCL) are also shown

on control charts. These limits are constructed so that if the process is operating under a stable

system of chance causes, the problem of an observation falling outside these limits is quite small.

Figure 6.7 shows a generalized representation of a control chart.

Control chart shows the performance of a process from two points of view. First, they show

a snapshot of the process at the moment the data are collected. Second, they show the process

trend as time progresses. Process trends are important because they help in identifying the outof-

control status if it actually exists. Also, they help to detect variations outside the normal

operational limits, and to identify the cause of variations. Fig. 6.7 shows a generalised representation

of a control chart.

6.5.6 Causes of Variation in Quality

The variation in the quality of product in any manufacturing process is broadly classified as:

(a) Chance causes

(b) Assignable causes.

(A) CHANCE

CAUSES

The chance causes are those causes which are inherit in manufacturing process by virtue of

operational and constructional features of the equipments involved in a manufacturing process.

This is because of—

1. Machine vibrations

2. Voltage variations

3. Composition variation of material, etc.

|

|

___ _________

_

_ ________

__

_____

_

They are difficult to trace and difficult to control, even under best condition of production.

Even though, it is possible to trace out, it is not economical to eliminate. The chance causes

results in only a minute amount of variation in process. Variation in chance causes is due to

internal factors only the general pattern of variation under chance causes will follow a stable

statistical distribution (normal distribution). Variation within the control limits means only random

causes are present.

(

B

) A

SSIGNABLE CAUSES

These are the causes which creates ordinary variation in the production quality.

Assignable cause’s variation can always be traced to a specific quality. They occur due to—

1. Lack of skill in operation

2. Wrong maintenance practice

3. New vendors

4. Error in setting jigs and fixtures

5. Raw material defects

Variation due to these causes can be controlled before the defective items are produced.

Any one assignable cause can result in a large amount of variation in process. If the assignable

causes are present, the system will not follow a stable statistical distribution. When the actual

variation exceeds the control limits, it is a signal that assignable causes extend the process and

process should be investigated.

6.6 STATISTICAL PROCESS CONTROL

Statistical process control (SPC) is the application of statistical techniques to determine whether

the output of a process conforms to the product or service design. It aims at achieving good

quality during manufacture or service through prevention rather than detection. It is concerned

with controlling the process that makes the product because if the process is good then the

product will automatically be good.

6.6.1 Control Charts

SPC is implemented through control charts that are used to monitor the output of the process and

indicate the presence of problems requiring further action. Control charts can be used to monitor

processes where output is measured as either variables or attributes. There are two types of

control charts: Variable control chart and attribute control chart.

1. Variable control charts: It is one by which it is possible to measures the quality

characteristics of a product. The variable control charts are X-BAR chart, R-BAR chart,

SIGMA chart.

2. Attribute control chart: It is one in which it is not possible to measures the quality

characteristics of a product, i.e., it is based on visual inspection only like good or bad, success

or failure, accepted or rejected. The attribute control charts are p-charts, np-charts, c-charts,

u-charts. It requires only a count of observations on characteristics e.g., the number of nonconforming

items in a sample.

|

C

HARACTERISTICS OF CONTROL CHARTS

A control chart is a time-ordered diagram to monitor a quality characteristic, consisting of:

1. A nominal value, or centre line, the average of several past samples.

2. Two control limits used to judge whether action is required, an upper control limit (UCL)

and a lower control limit (LCL).

3. Data points, each consisting of the average measurement calculated from a sample taken

from the process, ordered overtime. By the Central Limit Theorem, regardless of the

distribution of the underlying individual measurements, the distribution of the sample

means will follow a normal distribution. The control limits are set based on the sampling

distribution of the quality measurement.

B

ENEFITS OF

U

SING CONTROL CHARTS

Following are the benefits of control charts:

1. A control chart indicates when something may be wrong, so that corrective action can

be taken.

2. The patterns of the plot on a control chart diagnosis possible cause and hence indicate

possible remedial actions.

3. It can estimate the process capability of process.

4. It provides useful information regarding actions to take for quality improvement.

O

BJECTIVES OF

C

ONTROL CHARTS

Following are the objectives of control charts:

1. To secure information to be used in establishing or changing specifications or in determining

whether the process can meet specifications or not.

2. To secure information to be used on establishing or changing production procedures.

3. To secure information to be used on establishing or changing inspection procedures or

acceptance procedures or both.

4. To provide a basis for current decision during production.

|

5. To provide a basis for current decisions on acceptance for rejection of manufacturing or

purchased product.

6. To familiarize personnel with the use of control chart.

CONTROL CHARTS FOR VARIABLES

As the name indicates, these charts will use variable data of a process. X chart given an idea

of the central tendency of the observations. These charts will reveal the variations between

sample observations. R chart gives an idea about the spread (dispersion) of the observations. This

chart shows the variations within the samples.

X-Chart and R-Chart: The formulas used to establish various control limits are as follows:

(a) Standard Deviation of the Process,

, Unknown

R-Chart: To calculate the range of the data, subtract the smallest from the largest measurement

in the sample.

The control limits are: UCLR_D

4

RandLCLR_D3R

where R = average of several past R values and is the central line of the

control chart, and

D3

, D

4

= constants that provide three standard deviation (three-sigma)

limits for a given sample size

X -Chart: The control limits are:

UCLX = 2 2 X A RandLCL X A R X

where X = central line of the chart and the average of past sample mean’s, and

A2

= constant to provide three-sigma limits for the process mean.

(b) Standard Deviation of the Process,

, Known

Control charts for variables (with the standard deviation of the process,

, known) monitor

the mean, X , of the process distribution.

The control limits are:

UCL = X 2 X

and LCL = X 2 X

where X = centre line of the chart and the average of several past sample means, Z

is the standard normal deviate (number of standard deviations from

the average),

X

=

/ n and is the standard deviation of the distribution of sample means,

and n is the sample size

Procedures to construct X-chart and R-chart

1. Identify the process to be controlled.

|

_______ __

____

___

2. Select the variable of interest.

3. Decide a suitable sample size (n) and number of samples to be collected (k).

4. Collect the specified number of samples over a given time interval.

5. Find the measurement of interest for each piece within the sample.

6. Obtain mean (X) of each sample.

7. Establish control limits for X and R-charts.

C

ONTROL CHARTS FOR

A

TTRIBUTES

P-charts and C-charts are charts will used for attributes. This chart shows the quality characteristics

rather than measurements.

P

-CHART

A p-chart is a commonly used control chart for attributes, whereby the quality characteristic

is counted, rather than measured, and the entire item or service can be declared good or

defective.

The standard deviation of the proportion defective, p, is:

p

= p

_

1

p

_

/n, where n = sample size, and p = average of several past p values and

central line on the chart.

Using the normal approximation to the binomial distribution, which is the actual distribution

of p,

UCL

p

= Z

p

p

and LCLp = Z

p

p

where z is the normal deviate (number of standard deviations from the average).

ILLUSTRATIONS ON X BAR CHART AND R BAR CHART

(i) Standard Deviation of the Process,

, Unknown

ILLUSTRATION 1: Several samples of size n = 8 have been taken from today’s

production of fence posts. The average post was 3 yards in length and the average sample

range was 0.015 yard. Find the 99.73% upper and lower control limits.

SOLUTION: X = 3 yds

R = 0.015 yds

A2

= 0.37 from Statistical Table

UCL = X

A²R

3

0.37(0.015)

3.006 yds

LCL = X

A2

R

3

0.37(0.015)

2.996 yds

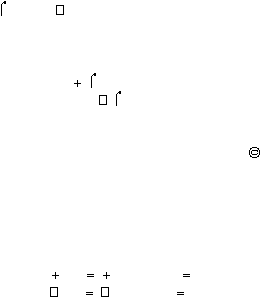

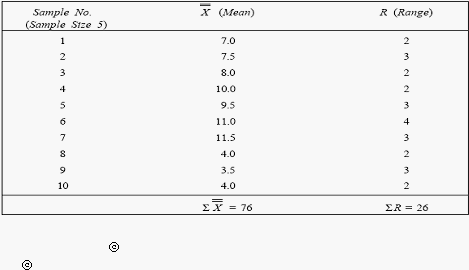

ILLUSTRATION 2 (Problem on X and R Chart): The results of inspection of 10

samples with its average and range are tabulated in the following table. Compute the

control limit for the X and R-chart and draw the control chart for the data.

|

SOLUTION: X =

X /No. of samples

R =

R/No. of samples

Therefore, X =

76

10

= 7.6

R =

26

10

= 2.6

For X chart

Upper Control Limit (UCL) = X + A2 R

Lower Control Limit (LCL) = X – A

2 ®

For R chart

Upper Control Limit (UCL) = D

4

R

Lower Control Limit (LCL) = D3

R

The values of various factors (like A², D

4

and D³

) based on normal distribution can be found

from the following table:

A2

= 0.58, D3 = 0 and D

4

= 2.11

Thus, for X chart

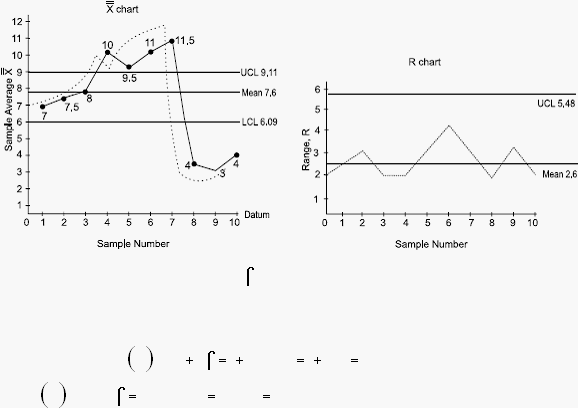

UCL = 7.6 + (0.58 × 2.6)

|

= 7.6 + 1.51 = 9.11

LCL = 7.6 – (0.58 × 2.6) = 6.09

For R chart UCL = 2.11 × 2.6 = 5.48

LCL = D3 × R = 0 × R = 0

These control limits are marked on the graph paper on either side of the mean value (line).

X and R values are plotted on the graph and jointed, thus resulting the control chart.

From the X chart, it appears that the process became completely out of control for 4th

sample over labels.

(ii) Standard Deviation of the Process,

, known

ILLUSTRATION 3: Twenty-five engine mounts are sampled each day and found to

have an average width of 2 inches, with a standard deviation of 0.1 inche. What are the

control limits that include 99.73% of the sample means (z = 3)?

SOLUTION: X

UCL

=

X

X

Z

2

3 0.1 25

2

0.06

2.06 inches

X

LCL =

X

X

Z

2

3 0.1 25

2

0.06

1.94 inches

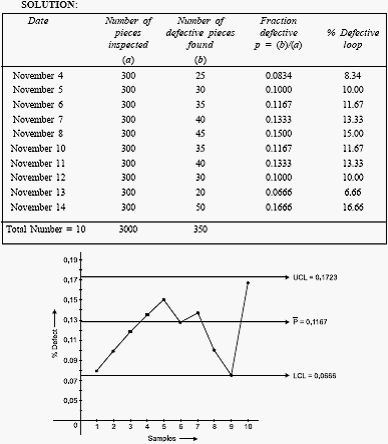

ILLUSTRATION 4 (Problem on p-Chart): The following are the inspection results

of 10 lots, each lot being 300 items. Number defectives in each lot is 25, 30, 35, 40,

45, 35, 40, 30, 20 and 50. Calculate the average fraction defective and three sigma

limit for P-chart and state whether the process is in control.

|

Upper Control Limit, UCL =

|

Lower Control Limit, LCL = p

P P

n

3

1

_ _

where p =

Total number of defective pieces found

Total number of pieces inspected

p =

350

3000

= 0.1167

and n = number of pieces inspected every day

= 300

Therefore,

p p

n

_

1

_

=

0 1167 1 0 1167

300

. ×

_

.

_

=

0 1167 0 8333

300

. × .

= 0.01852

and 3

1

.

p p

n

_

_

= 0.01852 × 3 = 0.05556

Thus, UCL = 0.1167 + 0.05556 = 0.17226 = 0.1723 (Approx.)

LCL = 0.1167 – 0.05566 = 0.06114 = 0.0611 (Approx.)

Conclusion: All the samples are within the control limit and we can say process is under

control.

T

YPES OF

S

AMPLING

E

RRORS

There are two types of errors. They are type-I and type-II that can occur when making

inferences from control chart.

Type-I: Error or

-error or Level of Significance

Reject the hypothesis when it is true.

This results from inferring that a process is out of control when it is actually in control. The

|

probability of type-I error is denoted by

, suppose a process is in control. If a point on the

control chart falls outside the control limits, we assume that, the process is out of control.

However, since the control limits are a finite distance (3

) from the mean. There is a small

chance about 0.0026 of a sample falling outside the control limits. In such instances, inferring the

process is out of control is wrong conclusion.

The control limits could be placed sufficiently far apart say 4 or 5

stand deviations on each

side of the central lines to reduce the probability of type-I error.

Type-II: Error or

-error

Accept the hypothesis when it is false.

This results from inferring that a process is in control when it is really out of control. If no

observations for outside the control limits we conclude that the process is in control while in

reality it is out control. For example, the process mean has changed.

___ _________

_

_ ________

__

_____

_

The process could out of control because process variability has changed (due to presence

of new operator). As the control limits are placed further apart the probability of type-II error

increases. To reduce the probability of type-II error it tends to have the control limits placed

closer to each other. This increases the probability of type-I error. Thus, the two types of errors

are inversely related to each other as the control limits change. Increasing the sample size can

reduce both

and

.

6.6.2 Acceptance Sampling

The objective of acceptance sampling is to take decision whether to accept or reject a lot based

on sample’s characteristics. The lot may be incoming raw materials or finished parts.

An accurate method to check the quality of lots is to do 100% inspection. But, 100%

inspection will have the following limitations:

_

The cost of inspection is high.

_

Destructive methods of testing will result in 100% spoilage of the parts.

_

Time taken for inspection will be too long.

_

When the population is large or infinite, it would be impossible or impracticable to inspect

each unit.

Hence, acceptance-sampling procedure has lot of scope in practical application. Acceptance

sampling can be used for attributes as well as variables.

Acceptance sampling deals with accept or reject situation of the incoming raw materials and

finished goods. Let the size of the incoming lot be N and the size of the sample drawn be n.

The probability of getting a given number of defective goods parts out a sample consisting of n

pieces will follow binomial distribution. If the lot size is infinite or very large, such that when a

sample is drawn from it and not replaced, then the usage of binomial distribution is justified.

Otherwise, we will have to use hyper-geometric distribution.

Specifications of a single sampling plan will contain a sample size (n) and an acceptance

number C. As an example, if we assume the sample size as 50 and the acceptance number as

3, the interpretation of the plan is explained as follows: Select a sample of size 50 from a lot and

obtain the number of defective pieces in the sample. If the number of defective pieces is less

than or equal to 3, then accept the whole lot from which the sample is drawn. Otherwise, reject

the whole lot. This is called single sampling plan. There are several variations of this plan.

In this process, one will commit two types of errors, viz., type-I error and type-II error. If

the lot is really good, but based on the sample information, it is rejected, then the supplier/

producer will be penalized. This is called producer’s risk or type-I error. The notation for this

error is

. On the other hand, if the lot is really bad, but it is accepted based on the sample

information, then the customer will be at loss. This is called consumer’s risk or type-II error. The

notation for this error is

. So, both parties should jointly decide about the levels of producer’s

risk (

) and consumer’s risk (

) based on mutual agreement.

|

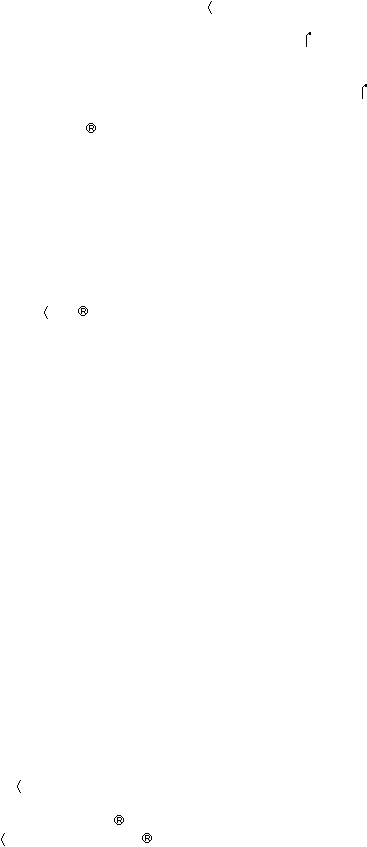

OPERATING CHARACTERISTIC CURVE (O.C. CURVE)

The concepts of the two types of risk are well explained using an operating characteristic curve.

This curve will provide a basis for selecting alternate sample plans. For a given value of sample

size (n), acceptance number (C), the O.C. curve is shown in Fig. 6.8.

_______ __

____

___

In Fig. 6.9, per cent defective is shown on x-axis. The probability of accepting the lot for

given per cent defective is shown on y-axis. The value for per cent defective indicates the

quality level of the lot inspected. AQL means acceptable quality level and LTPD indicates lot

tolerance per cent defectives. These represent quality levels of the lot submitted for inspection.

If the quality level of the lot inspected is at AQL or less than AQL, then the customers are

satisfied with the quality of the lot. The corresponding probability of acceptance is called

1 –

. On the other hand, if the quality level is more than or equal to LTPD, the quality of

the lot is considered to be inferior from consumer’s viewpoint. The corresponding probability

of acceptance of the lot is called

. The quality levelling between AQL and LTPD is called

indifferent zone.

Fig. 6.9 Operating characteristic curve

So, we require

,

, AQL and LTPD to design a sample plan. Based on these, one can

determine n and C for the implementation purpose of the plan.

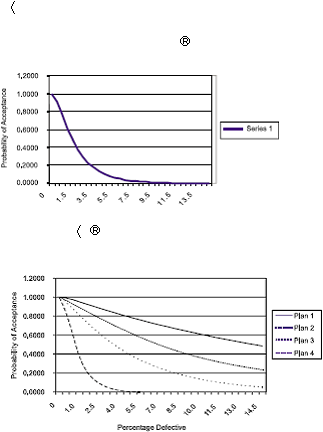

Fig. 6.10 shows a various O.C. curves for different combinations of n and C.

|

___ _________

_

_ ________

__

_____

_

SINGLE SAMPLING PLAN

The design of single sampling plan with a specified producer’s risk and consumer’s risk is

demonstrated in this section. The required data for designing such plan are as follows:

(a) Producer’s Risk (

)

(b) Consumer’s Risk (b)

(c) Acceptable Quality Level (AQL)

(d) Lot Tolerance Per cent Defectives (LPTD)

The objective of this design is to find out the values for the sample size (n) and acceptance

number (C). The values for n and C are to be selected such that the O.C. curve passes through

the following two coordinates:

_

Coordinate with respect to the given

and AQL.

_

Coordinate with respect to the given

and LTPD.

But, the values of n and C should be integers. So, it will be very difficult to find n and C

exactly for the given parameters of the design. Hence, we will have to look for approximate

integer values for n and C such that the O.C. curve more or less passes through the above two

coordinates.

6.7 QUALITY CIRCLES

The quality circles begun in Japan in 1960s. The concept of quality circles is based on the

participating style of management. It assumes that productivity will improve through an uplift of

morale and motivations which are in turn achieved through consultation and discussion in informal

groups. One organizational mechanism for worker participation in quality is the quality circle. It

is typically an informal group of people that consists of operators, supervisors, managers and so

on who get together to improve ways to make the product or deliver the service.

According to Juran, quality circle defined as “a group of work force level people, usually

from within one department, who volunteer to meet weekly (on company time) to address quality

problems that occur within their department.”

Quality circle members select the problems and are given training is problem-solving

techniques. A quality circle can be an effective productivity improvement tool because it

generates new ideas and implements them. Where the introduction of quality circle is

capably planned and where the company environment is supporting they are highly

successful.

The benefits fall into two categories: those are measurable saving and improvement in the

attitudes and behaviour of people. Quality circles pursue two types of problems, those concerned

with the personal well being of the worker and those concerned with the well being of company.

6.7.1 Benefits of QC

The most important benefit of quality circles is their effect on people’s attitudes fall into three

categories

|

|

_______ __

____

___

1. Quality Circles Effect on Individual Characteristics

(a) Quality circles enable the individual to improve personal capabilities—group participation

and learning specific problem-solving tools.

(b) Quality circles increase the individual’s self-respect.

(c) Quality circles help worker change certain personality characteristics—shy person become

as active.

2. Quality Circles Effect on Individuals Relations with Other

(a) Quality circles increase the respect of the supervisor for the worker.

(b) Quality circles increase workers understanding of the difficulties faced by supervisors—

problem selection, solving and implementations.

(c) Quality circle increase management’s respect for worker.

3. Quality Circles Effect on Workers and Their Attributes

(a) Quality circles change some workers negative attitudes.

(b) Quality circle reduces conflict stemming from the working environment.

(c) Quality circles help workers to understand better the reasons while many problems

solved quickly.

Quality circles, as a management tool, are based on the following basic principles of

people:

(a) People want to do a good job.

(b) People want to be recognized as intelligent, interested employees and to participate in

decisions affecting their work.

(c) People want information to better understand goals and problems of their organization

and make informed decisions.

(d) Employees want recognition and responsibility and a feeling of self-esteem.

Motivational methods are not enough for successful quality circle programs. Management

support, technical knowledge, and statistical procedures are essential.

6.8 TOTAL QUALITY MANAGEMENT

Now-a-days, customers demand products/services with greater durability and reliability at the

most economic price. This forces producers to strictly follow quality procedures right from design

till shipment and installation of the products. So that goal of any competitive industry is to provide

a product or service at the most economical costs, ensuring full customer satisfaction. This can

be achieved through Total Quality Management (TQM), because, quality is not a technical

function, but a systemic process extending throughout all phases of the business, e.g., marketing,

design, development, engineering, purchasing, production/operations.

As per Feigebaum, “Total Quality Management is an effective system of integrating the

quality development, quality maintenance and quality improvement efforts of various groups in an

organization so as to enable marketing, engineering, production and service at the most economical

levels which allow for full customer satisfaction”.

|

|

___ _________

_

_ ________

__

_____

_

6.8.1 Benefits of TQM

The benefits of TQM can be classified into the following two categories:

1. Customer satisfaction oriented benefits.

2. Economic improvements oriented benefits.

1. Customer satisfaction oriented benefits: The benefits under this category are listed below:

(a) Improvement in product quality.

(b) Improvement in product design.

(c) Improvement in production flow.

(d) Improvement in employee morale and quality consciousness.

(e) Improvement of product service.

(f) Improvement in market place acceptance.

2. Economic improvements oriented benefits: The benefits under this category are as

follows:

(a) Reductions in operating costs.

(b) Reductions in operating losses.

(c) Reductions in field service costs.

(d) Reductions in liability exposure.

6.9 ISO 9000 SERIES

ISO stands for International Organization for Standardization. It is an international body, which

consists of representatives from more than 90 countries. The national standard bodies of these

countries are the members of this organization. Bureau of Indian Standards (BIS) are the Indian

representative to ISO, ISO and International Electro Technical Commission (IEC)) operate jointly

as a single system. These are non-governmental organizations, which exist to provide common

standards on international trade of goods and services.

ISO 9000 standards expect firms to have a quality manual that meets ISO guidelines,

documents, quality procedures and job instructions, and verification of compliance by third-party

auditors. ISO 9000 series has five international standards on quality managements. They are:

1. ISO 9000 — Quality management and Quality assurance standards

2. ISO 9001 — Quality systems: Quality in design

3. ISO 9002 — Quality systems: Production and Installation

4. ISO 9003 — Quality systems: Final inspection and test

5. ISO 9004 — Quality management and systems

6.9.1 Objectives of ISO 9000 Series